PRECONDITIONING SERVICES

Preconditioning services are performed on non-hermetic surface mount packages to determine the moisture absorption integrity. The following steps are typical for most preconditioning tests.

Preconditioning services are performed on non-hermetic surface mount packages to determine the moisture absorption integrity. The following steps are typical for most preconditioning tests.

- PRE-CSAM – CSAM testing to confirm if any Delamination or other anomalies exist prior to Pre-Conditioning

- Temp Cycle – 5 cycles of temperature cycling

- Bake Oven – 24 hours bake to drive out any pre-existing moisture

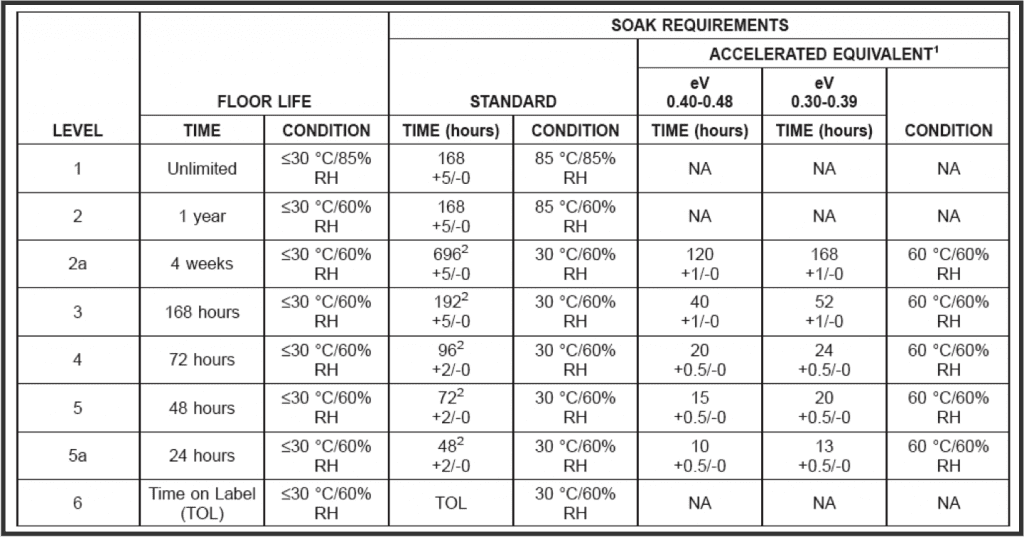

- Moisture Soak – As required by the customer

- Solder Reflow – 3 cycles of solder reflow process

- POST-CSAM – CSAM testing again to determine if any delamination occurred during the test

This is a very important test as it has been determined that during the solder reflow process the sudden expansion of any trapped moisture inside the component can result in internal separation (delamination) of a plastic encapsulation from the die or lead-frame, wire bond damage, die damage and internal cracks. In most severe cases, the components will bulge and pop, this is known as the “popcorn” effect. All of these samples must also pass the electrical test. Most of the package qualification plans require that devices be preconditioned prior to subjecting them to Temperature Cycle, Thermal Shock, HAST , Temperature Humidity and Pressure Pot testing.

Reference spec:

IPC/JEDEC J-STD-020

Air Convection Simulation (Reflow)

- Heller 1700 and 1800 systems

- PC driven for easy programming

- Three thermocouple profiling capability

- Temperature range up to 300° C

- Variable belt speeds

- Adjustable ramp rates

- Temperature profiles generated with every job

- Equipped with all the safety features