TEMPERATURE CYCLING SYSTEMS

With multiple Systems we provide complete flexibility in various temperature ranges.

- Variable temperature ranges

- One and two zone chambers

- Easy programming features

- Equipped with all the safety features

- Cycle counters

- Adjustable soak and dwell times

- Fully calibrated

THERMAL SHOCK SYSTEMS

Our liquid-to-liquid Thermal Shock System provides complete flexibility in various temperature ranges.

- Variable temperature ranges

- Easy programming features

- Equipped with all the safety features

- Cycle counters

- Adjustable soak and dwell times

- Fully calibrated

AUTOCLAVE (PRESSURE POT) SYSTEMS

- Saturated stainless steel chambers.

- Horizontal chambers.

- Operation at 121C and 100% relative humidity.

- Easy to program and setup test conditions.

- Stainless steel wire mesh baskets for holding devices during test.

- Built-in indicators for temperature, humidity and pressure.

- Built-in safety features for over temperature and over pressure condition.

TEMPERATURE HUMIDITY SYSTEMS

- Programmable humidity and temperature ranges.

- Universal racks for bias testing.

- Stainless steel interior.

- Signal conditioner that converts dry/wet bulb signals to direct % R.H.

- LED display for temperature and humidity.

- Many conditions available

- Safety features for over temperature condition.

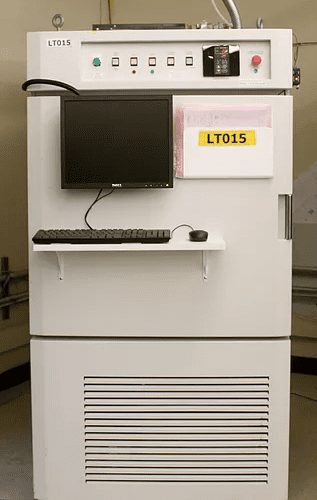

LOW TEMPERTURE STORAGE

The test is applicable for evaluation, screening, monitoring, and/or qualification of all solid state devices Low Temperature storage test is typically used to determine the effect of time and temperature, under storage conditions, for thermally activated failure mechanisms of solid state electronic devices, including nonvolatile memory devices (data retention failure mechanisms). During the test reduced temperatures (test conditions) are used without electrical stress applied. This test may be destructive, depending on Time, Temperature and Packaging (if any).

HIGH TEMPERTURE STORAGE

The test is applicable for evaluation, screening, monitoring, and/or qualification of all solid state devices. The high temperature storage test is typically used to determine the effects of time and temperature, under storage conditions, for thermally activated failure mechanisms and time-to-failure distributions of solid state electronic devices, including nonvolatile memory devices (data retention failure mechanisms). Thermally activated failure mechanisms are modeled using the Arrhenius Equation for acceleration. During the test, accelerated stress temperatures are used without electrical conditions applied. This test may be destructive, depending on time, temperature and packaging (if any).

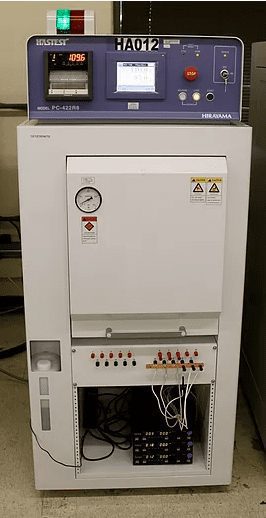

HIGHLY ACCELERATED STRESS TEST (HAST)

HAST is performed for the purpose of evaluating the reliability of non-hermetic packaged solid-state devices in humid environments. It employs severe conditions of temperature, humidity, and bias (under 2 atmospheres of pressure), which accelerate the penetration of moisture through the external protective material (encapsulant or seal) o along the interface between the external protective material and the metallic conductors which pass through it.

HAST usually activates the same failure mechanisms as the "85/85" Steady-State Humidity Life Test (JEDEC Standard JESD22-A101), within 96hrs of stress rather than the 1000hrs of stress required "85/85".

Reference Spec:

| JESD22-A110, JESD22-A118 (Unbiased HAST) |

THB – TEMPERATURE HUMIDITY BIAS TEST

This Steady-State Temperature Humidity Bias Life Test is performed to evaluate the reliability of non-hermetic packaged IC devices in humid environments. Temperature, humidity, and bias conditions are applied to accelerate the penetration of moisture through the external protective material (encapsulated or seal) or along the interface between the external protective material and the metallic conductors which pass through it.

Reference Spec:

JESD22-A101C (This JEDEC Standard is also used for Automotive)

POWER AND TEMPERATURE CYCLING TESTING (PTC)

This test is performed to determine the ability of a device to withstand alternate exposures at high and low temperature extremes with operating biases periodically applied and removed.

PTC System: 144 signals, 8 power supplies, Logging, Sine wave option, temperature and power cycle.

Reference spec:

JESD22-A105 (This JEDEC Standard is also used for Automotive)

TEMPERATURE CYCLING - RAPIDTHERM (RT2C-3-3-A/C).

With multiple Systems we provide complete flexibility in various temperature ranges.

- 2 cubic ft. single chamber

- Capable of JEDS-A104 requirements

- Temperature range -75C to 200C

- Thermal control to DUT or Chamber

- Ramp rates as fast as 25C/min

- SLOWER RATES ARE RAMP CONTROLLED SUCH AS 10C/MIN OR 15C/MIN