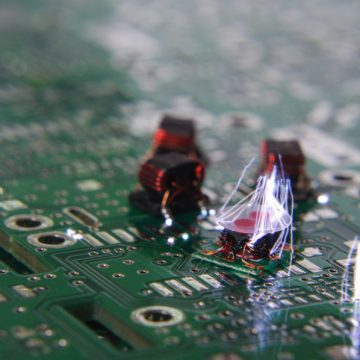

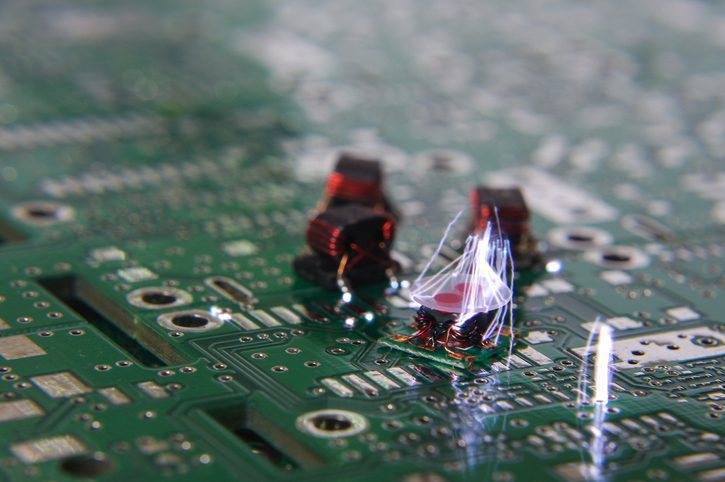

If you've ever seen someone discharge static electricity by touching a metal doorknob after walking across a carpeted floor, then you've witnessed electrostatic discharge (ESD). ESD can also occur between two objects that are not in contact with each other, which is why electronic manufacturers subject their products to ESD testing.

In this article, we'll explain the basics of ESD testing and provide an overview of the two most common test methods.

What is ESD Testing?

ESD testing is a process used to determine whether or not a device can withstand being exposed to electrostatic discharge. This type of testing is important for electronic manufacturers because even a small amount of static electricity can damage sensitive components. As a result, devices that are prone to damage from ESD must be properly shielded and/or grounded during storage, handling, and use.

There are two main types of ESD tests: air discharge and contact discharge. Air discharge tests involve moving a charged generator or discharge object (e.g., an ESD gun) towards the device under test. The purpose of this test is to simulate what would happen if someone were to accidentally touch the device with their finger while carrying a static charge.

Contact discharge tests, on the other hand, involve actually touching the device under test with either a charged finger or probe. This type of test is typically used to determine the level of protection that a product's packaging provides against ESD damage.

ESD testing is an important process used by electronic manufacturers to ensure that their products can withstand being exposed to electrostatic discharge. There are two main types of ESD tests: air discharge and contact discharge. Air discharge tests involve moving a charged generator or discharge object towards the device under test, while contact discharge tests involve actually touching the device under test with either a charged finger or probe. By understanding the

basics of how these tests work, you can make sure that your products are properly protected against electrostatic damage.